Masonry wall systems are building systems that use masonry materials such as brick, stone, or concrete blocks to construct walls. These materials are typically stacked on top of each other and held together with mortar.

Masonry is the oldest technique used for constructing buildings or structures. Masonry buildings are specifically stone masonry, which provides strength, and durability to the structure and also controls indoor and outdoor temperatures. Even reinforced masonry also resists hurricane and seismic forces.

Masonry has been used as the construction material for several thousand years and still, and it’s popular. All remarkable and historic buildings all over the world are constructed using reinforced concrete (Masonry). So, what exactly is masonry and what are the different types of these structures? Let’s find out!

Contents

- What are Masonry Walls?

- What Is The Purpose of Adding Masonry?

- Types of Masonry Walls

- Based on Functions

- Based on Bonding Material

- Based on Thickness

- What is The Typical Size of Masonry Walls?

- How Do You Choose Between Masonry Types?

- Cost

- Durability

- Aesthetics

- Location

- Type

- Lux Construction Services in Los Angeles

What are Masonry Walls?

Masonry refers to the use of brick, concrete blocks, structural clay tiles, and stone in building construction. These materials are held together with mortar. Mortar for masonry isn’t cement mix. The mortar mix contains lime, sand, and gypsum, each in the proper proportions. On the other hand, cement mix has stones in the sand and doesn’t contain lime.

Among all types of buildings or structures, masonry wall systems are the most durable. Masonry is the term used to describe construction utilizing mortar to join blocks, stones, marbles, rocks, solid squares, tiles, and so on. In a mortar, restricting material is mixed with sand. Besides concrete, lime, soil, or any other constructing material, restricting materials can also be concrete.

Masonry units (brick, stone, or concrete blocks) are used for various purposes. There are some workers who work on building constructions, while some make barriers to separate property lines, and others build house walls for structural purposes.

What Is The Purpose of Adding Masonry?

There are several advantages of masonry units. Here are the followings:

- Masonry is non-combustible. It improves fire protection for the building and its residents. Fireplaces are commonly made of masonry.

- Masonry has high resistance against rotting, pests, weather, and natural disasters such as hurricanes and tornadoes.

- Depending on the materials used and the expertise of the workers, masonry structures can provide an attractive rustic or elegant look to a home or building.

- Despite its durability and resistance, Masonry can withstand heavy compressive loads.

- Buildings with masonry units have a higher thermal mass.

- No building type has a longer lifespan than a masonry building.

- Construction using masonry increases its resale value.

- A masonry structure won’t rot or be destroyed by insects such as ants or termites.

- The masonry construction method is cost-effective in terms of labor and materials in comparison to wood.

Hence, there is no doubt to say that reinforced brick walls are a great option to add beauty and value to any construction. Are you planning to build a masonry building? LUX Construction is here to assist you. We have a team of general contractors who help in achieving your plans.

So, if you need help with this, reach out to us today!

Types of Masonry Walls

Well, there are different types of masonry walls, depending on the motor mix materials, function, and thickness. Take a look at the following!

-

Based on Functions

In terms of functions, masonry wall systems are either load-bearing or non-load-bearing walls. Load-bearing walls support the structure of the building. Non-load bearing walls are merely partitions that divide a building’s rooms. As we discussed above, reinforced brick walls add strength and lastingness, maintain temperature, and protect buildings from the outside world.

-

-

Load Bearing Masonry Walls

-

From 1700 to the mid-1990s, load-bearing masonry construction was the most widely used option for large buildings. This construction works on the principle that every wall carries the load. In this structure, thick, heavy masonry walls made of brick, stone, or reinforced concrete support both the horizontal floor slabs and the entire structure. The weight of the walls holds the building together and stabilizes it against external forces such as earthquakes and wind.

Because reinforced brick wall construction doesn’t perform well in earthquakes, load-bearing construction rarely is used. Additionally, it’s extremely labor- and material-intensive. You can’t make holes in the wall to connect rooms. Otherwise, it would damage the structure.

-

-

Non-Load Bearing Masonry Walls

-

Nowadays, most frame structures aren’t non-load bearing. But, these types of buildings have very thin and light internal and external walls and support floor slabs.

Modern multi-story buildings are constructed with non-load-bearing walls. And, you can do customization, major alteration, and renovation in a non-load bearing structure without affecting the parent structure. Additionally, it performs very well in earthquakes, is low labor & material intensive, plus very flexible in terms of internal floor layout.

-

Based on Bonding Material

Masonry walls can be constructed using age-old materials such as burnt clay bricks to the latest masonry materials such as Autoclave Aerated Concrete (AAC) blocks. In addition, to fly ash bricks and solid/hollow concrete blocks, cellular lightweight blocks can also be used. It’s important to choose a brick/block for concrete wall systems carefully as each has its pros and cons.

-

-

Solid Block Masonry

-

Pros: Solid block masonry has a compressive strength of 5 – 8 Mpa. The blocks can be manufactured at the site for economical production and do not need to be transported or taxed. Among their class, they have the lowest water absorption.

Cons: Solid concrete blocks have a very high density of 2100 to 2200 kg/cum due to which the dead load on the structure is high and the reinforcement consumption increases. It is difficult to handle these blocks. The dimensions of these blocks vary quite a bit. Installation of electrical and plumbing systems is labor-intensive and time-consuming. The typical sizes of such masonry are 390 x 190 x 190mm, 390 x 190 x 140mm, and 390 x 190 x 90mm.

This concrete wall system is best for low-rise construction!

-

-

Hollow Concrete Block Masonry

-

Pros: Hollow block masonry has a good compressive strength of 5 – 8 Mpa. These aren’t only light-weight with a density of 1250 to 1400 kg/cum but the dead load on structure is also less. These blocks can be manufactured at the site for economical production (no transportation or taxes).

Cons: The installation of services requires concrete filling after chiseling. These blocks have a high level of waste. The typical sizes are 390 x 190 x 190mm, 390 x 190 x 140mm, and 390 x 190 x 90mm.

This reinforced brick wall is best for low-rise construction!

-

-

Lightweight Aerated Concrete (AAC) Block Masonry

-

Pros: AAC blocks are lightweight with a density of 600 – 700 kg/cum. Thus, they become easy to handle and reduce the dead load on the structures. For service installation (electrical and plumbing), it is also easy to chisel. These blocks have better thermal and acoustic properties, very high dimension accuracy, and consumption of plaster is low in comparison to other block masonries.

Cons: Its compressive strength is 3 – 4mpa, which is low in comparison to other substitutes. These blocks can’t be manufactured at the site because better quality control is required during production. These blocks are prone to breakages/wastage, that’s why they need to be handled properly. These blocks are expensive per unit. And, the typical sizes are 600 x 200 x 200 mm, 600 x 200 x 150mm, 600 x 200 x 100 mm.

This masonry is best for high-rise construction!

-

-

Cellular Lightweight Concrete (CLC) Block Masonry

-

Pros: These blocks are lightweight and have a density of 550 to 650 kg/cum. In addition, they have high dimension accuracy, less dead load on structures, ease in chiseling for electrical and plumbing installation, low-time consumption, and better thermal and acoustic properties. It can be manufactured at the site (no transportation or taxes) for economical production.

Cons: These blocks have a compressive strength of 3 – 4MPa, which is low in comparison to other substitutes. Due to low breakages/wastages, they require better quality control during production. The typical sizes are 600 x 200 x 200 mm 600 x 200 x 150mm, and 600 x 200 x 100 mm.

This masonry is best for high-rise construction!

-

-

Fly Ash Brick Masonry

-

Pros: Its compressive strength lies between 3.5 – 5mpa as good as its substitutes. These blocks/bricks can be manufactured at the site (no transportation and taxes). These bricks are easy to chisel for services, such as electrical and plumbing.

Cons: Fly Ash bricks have a very high density i.e. 2100 to 2200 kg/cum. It increases the dead load of the structure. Dimensional variability and plaster consumption are high for these bricks. The typical sizes are 230 x 150 x 80 mm, 230 x 150 x 100 mm, and 230 x 100 x 100 mm.

This masonry is best for both low and high-rise construction!

-

-

Burnt Clay Brick Masonry

-

Pros: These blocks have moderate unit weight, density is 1700 to 1800 kg/cum, compressive strength is 3.5 – 5MPa, better thermal properties, ease in chiseling for services (Electrical and Plumbing) installation, less labor intensive, and low time-consuming. These blocks/bricks are manufactured at the site (no transportation and taxes).

Cons: It has high dimension variations, can’t be manufactured at the site, highest water absorption among its substitutes, and is prone to efflorescence. You might observe under-burnt and over-burnt clay bricks. The availability of good quality bricks is a major concern. The typical sizes are 230 x 190 x 100 mm, and 230 x 100 x 75 mm.

This masonry is best for both low and high-rise construction!

-

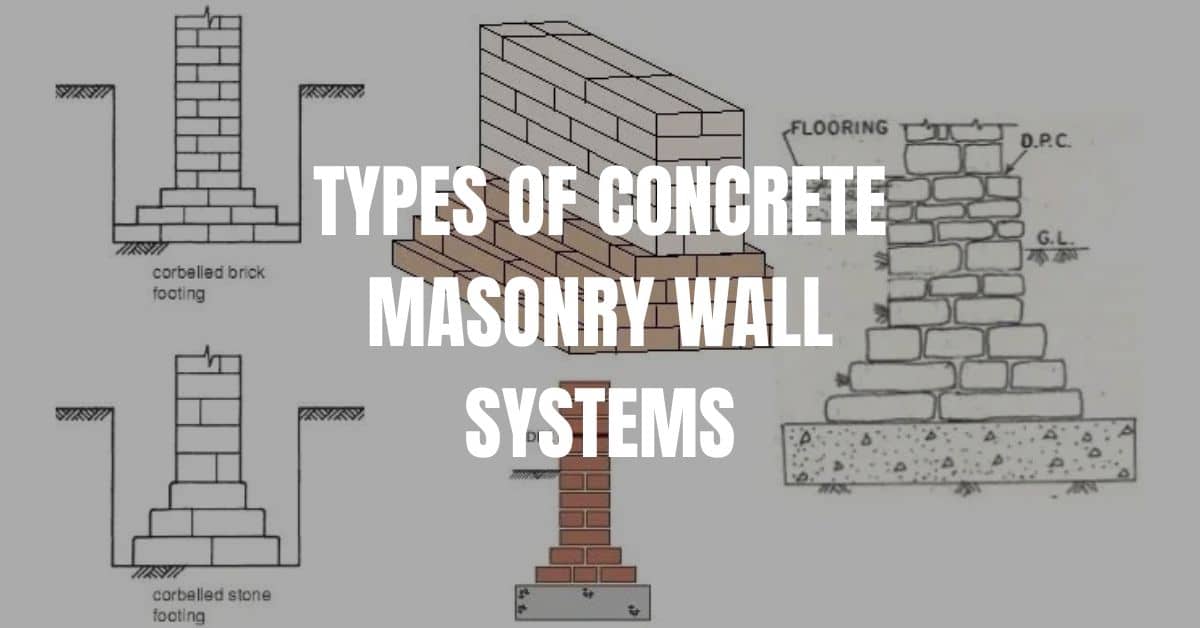

Based on Thickness

Always remember that the thickness of stone/block walls is different based on their size. The most popular wall thicknesses in block construction are 100 mm, 150 mm, and 200 mm. For dressed stone, the minimum thickness would be 23 cm (230 mm) and for undressed stone, 35 cm (350 mm).

-

-

One Brick Masonry

-

It’s sometimes referred to as a 9 inches/23 cm wall. Buildings use one brick masonry as both exterior and interior walls.

-

-

Half Brick Masonry

-

The half-brick wall is sometimes referred to as a 4 inches/13 cm wall. Buildings generally use half-brick masonry for internal walls. Load-bearing structures are rarely used due to their inability to support the load.

-

-

One and Half Brick Masonry

-

A one-and-a-half brick wall is also known as a 14-inch/35-centimeter wall. For buildings with more than four stories, one-and-a-half brick masonry is used for the foundation as well as the lower floors.

There has been evidence that these brick wall types have lasted for hundreds or even thousands of years. Over 70% of the construction in the world is made of masonry. Across the globe, masonry is growing in popularity. There are a number of the world’s essential monuments that were constructed with different forms of masonry. Architects and contractors choose masonry due to its high durability, beauty, and versatility.

Do you want to know how to retrofit masonry buildings? Read in our post “Retrofitting of Unreinforced Masonry Buildings”.

What is The Typical Size of Masonry Walls?

In a load-bearing masonry structure, bricks are typically 225mm (9′′) thick.

The outer walls of a Framed Structure are usually 200mm (8′′) thick and the inner walls are 150mm (6′′) thick. In the absence of concealed electrical and plumbing provisions, 4″ thick walls can also be used for internal partitions.

The residential wall thickness is always calculated without the plaster thickness. So, if a wall has plaster on both sides, its actual thickness will be 25 to 35mm greater than what is shown in an architectural drawing.

How Do You Choose Between Masonry Types?

When choosing between masonry types, there are several factors to consider such as cost, durability, aesthetics, and location.

-

Cost

Cost is an important consideration, as some masonry types can be quite expensive. Brick and stone, for example, are generally more expensive than concrete blocks.

-

Durability

Durability is another important factor. Brick and stone are both very durable and long-lasting materials, while concrete block is also durable but may not last as long.

-

Aesthetics

Aesthetics is another consideration. Brick and stone can give a more traditional, timeless look to a building, while the concrete block can have a more modern, industrial look.

-

Location

Location is also a factor. In areas with high humidity or freeze-thaw cycles, brick and stone may not be the best choice as they can be more prone to cracking and deterioration.

-

Type

Ultimately, the decision of which masonry type to use will depend on a combination of these factors and the specific requirements of the project.

If you are unsure about a particular masonry style, speak with a contractor. In this way, you’ll be able to understand how each type of masonry will affect your project as a whole. Additionally, they can explain the difference between unreinforced masonry walls and reinforced masonry. The best means of making this decision is to have a professional general contractor on your side.

Lux Construction Services in Los Angeles

Masonry services from your contractor help you design the exact building you need. Concrete pouring, bricklaying, or stucco laying are all tasks that your contractor can complete. It takes true professionals to accomplish those tasks. After the work is completed, a contractor will ensure that the building is safe for you and your employees.

We offer more than just masonry services. Building a commercial facility or office space that suits your business’s needs and culture is what we do. Every masonry project we take on is designed and built by an architect, project manager, and engineer, so you don’t have to manage multiple contractors.

Are you planning to use certain types of masonry in your construction project? Get in touch with LUX Construction Group today.